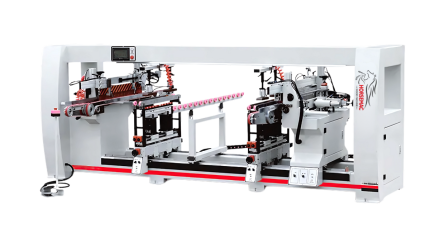

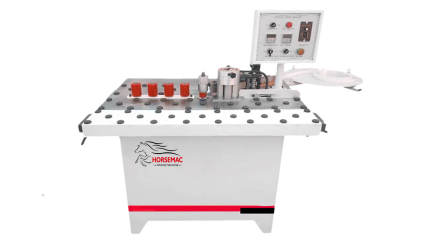

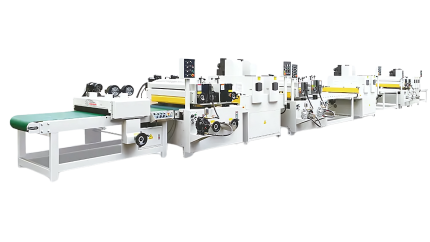

Double Heads Lacquer Sanding Machine

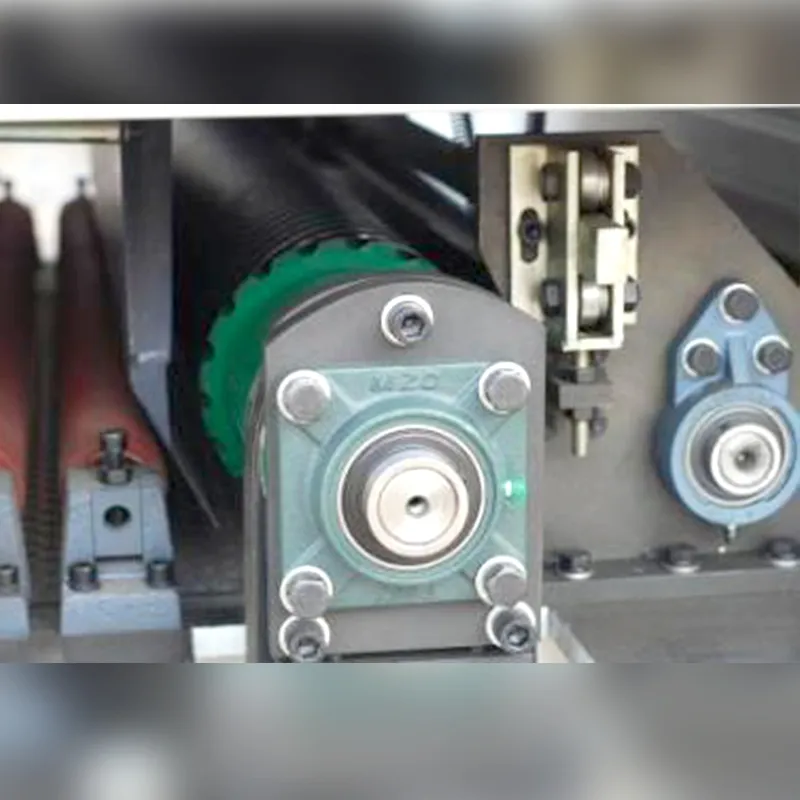

- 2 RUBBER ROLLER PLUS BUILD IN BRUSH FOR BOARDS AFTER PAINTING

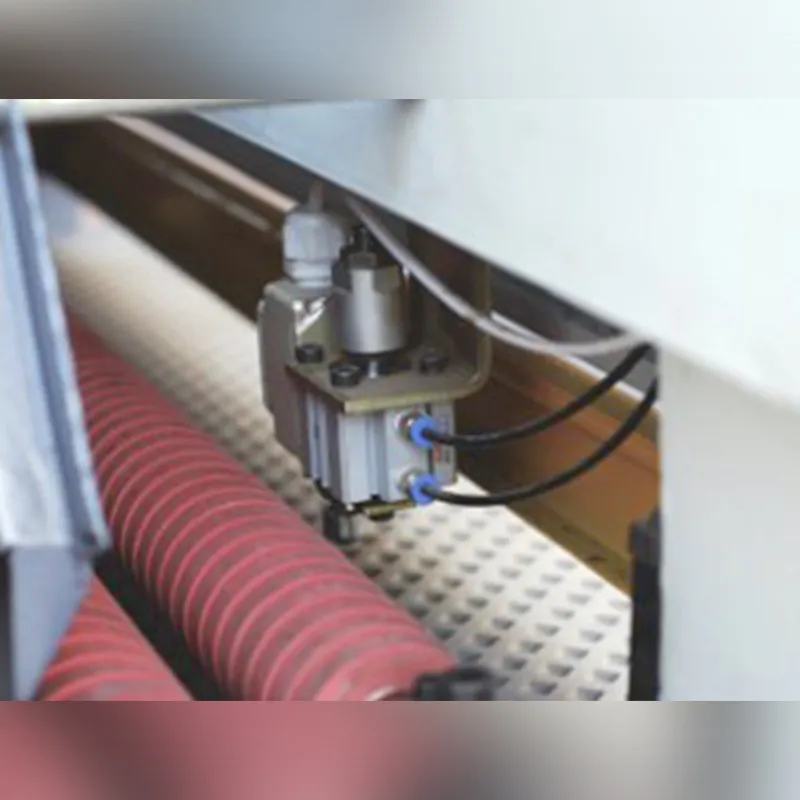

- 2 PCS OF SWING SANDING BELT DUST REMOVE TO KEEP BELT CLEAN TO EXTEND THE SANDING BELT WORK TIME

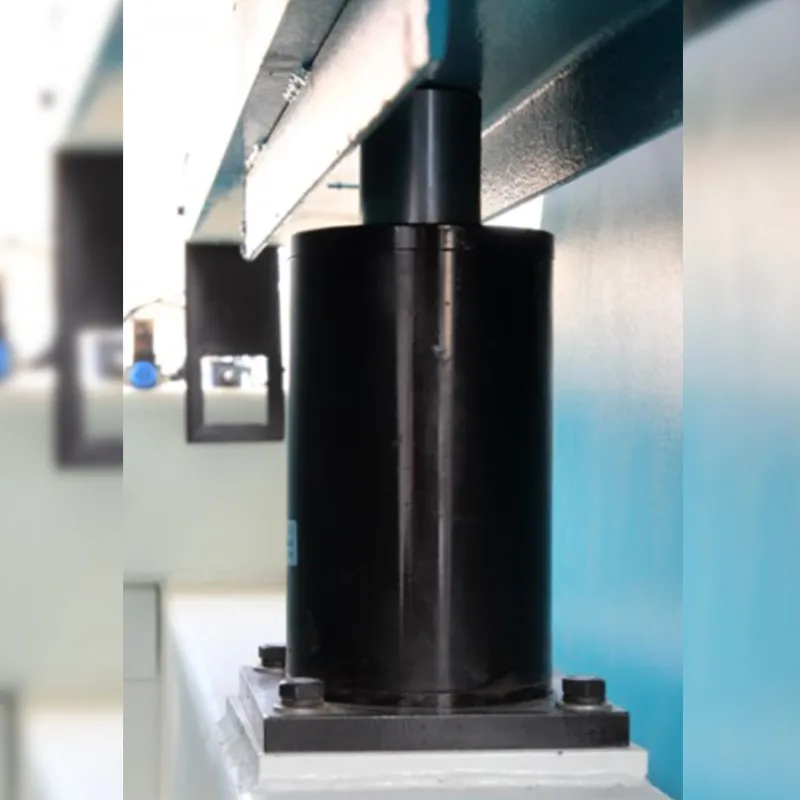

- HARDENING TREATMENT MACHINING CENTER TO PROCESS THE MACHINE FRAME, STABLE AND PRECISION

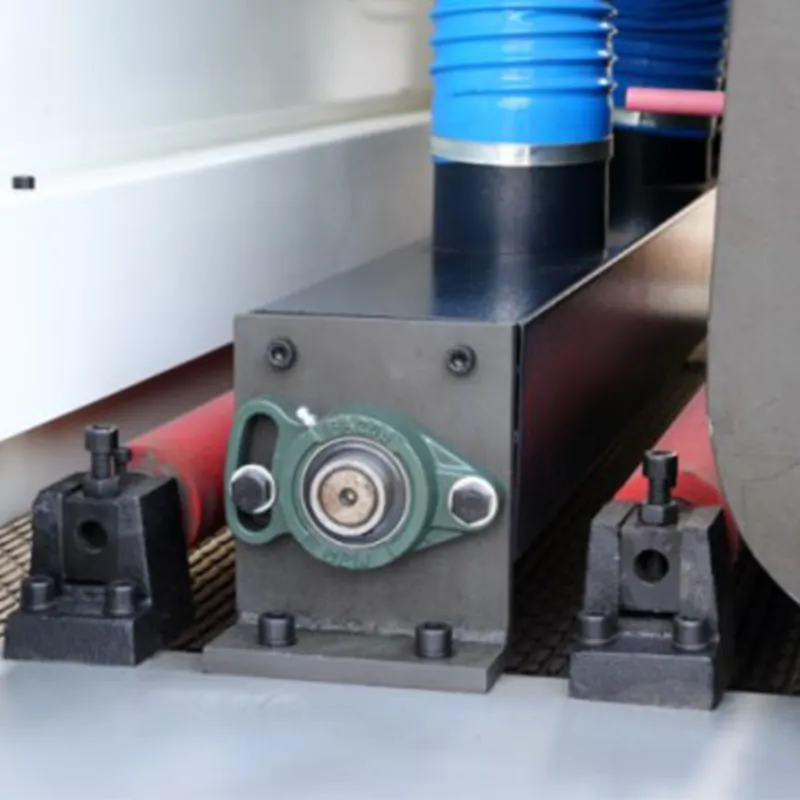

- ASSEMBE DYNAMICALLY BALANCED ROLLERS ON THIS MACHINE AND OTHER GOOD QUALITY PARTS, ALL OF THESE TO ENSURE THE ENTIRE MACHINE HAS HIGH PRECISION AND LONG TERM RELIABILITY

| Model | HM630R-R | HM1000R-R | HM1300R-R |

| Working width | 30-630mm | 30-1000mm | 30-1300mm |

| Working thickness | 2-100mm | 2-100mm | 2-100mm |

| Abrasive belt speed | 3-16m/s | 3-16m/s | 3-16m/s |

| Feed speed | 5-25m/min | 5-25m/min | 5-25m/min |

| Size of abrasive belt | 650*1900mm | 1020*2000mm | 1320*2200mm |

| Sanding belt (paper) | 320/400 Mesh | 320/400 Mesh | 320/400 Mesh |

| #1 sanding unit | 4kw, Ø190mm, 30sh eccentric rubber | 7.5kw, Ø190mm, 30sh eccentric rubber | 11kw, Ø240mm, 30sh eccentric rubber |

| #2 sanding unit | 4kw, Ø190mm, 25sh rubber | 7.5kw, Ø190mm, 25sh rubber | 11kw, Ø240mm, 25sh rubber |

| Total motor power | 9.7kw | 17kw | 26kw |

| Working air pressure | ≥0.6Mpa | ≥0.6Mpa | ≥0.6Mpa |

| Speed of sucked air | ≥25m/s | ≥25m/s | ≥25m/s |

| Overall dimensions | 1850*1270*2000mm | 1862*1680*2040mm | 2260*2020*2150mm |

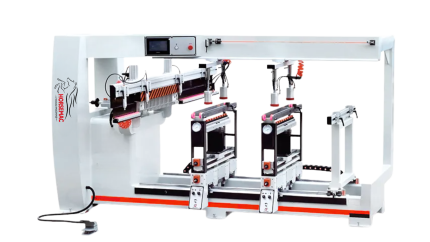

Drilling & Boring

Drilling & Boring Edge Banding

Edge Banding CNC Router

CNC Router Membrane Press Machine

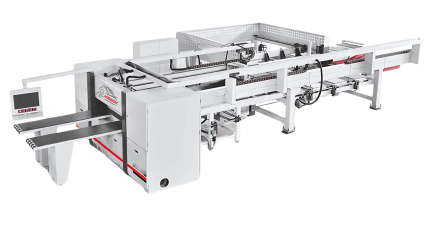

Membrane Press Machine Panel Saw

Panel Saw Sanding Machine

Sanding Machine Log Process Machine

Log Process Machine Compressors

Compressors Dust Extraction

Dust Extraction