Heavy Duty Brush Sanding Machine

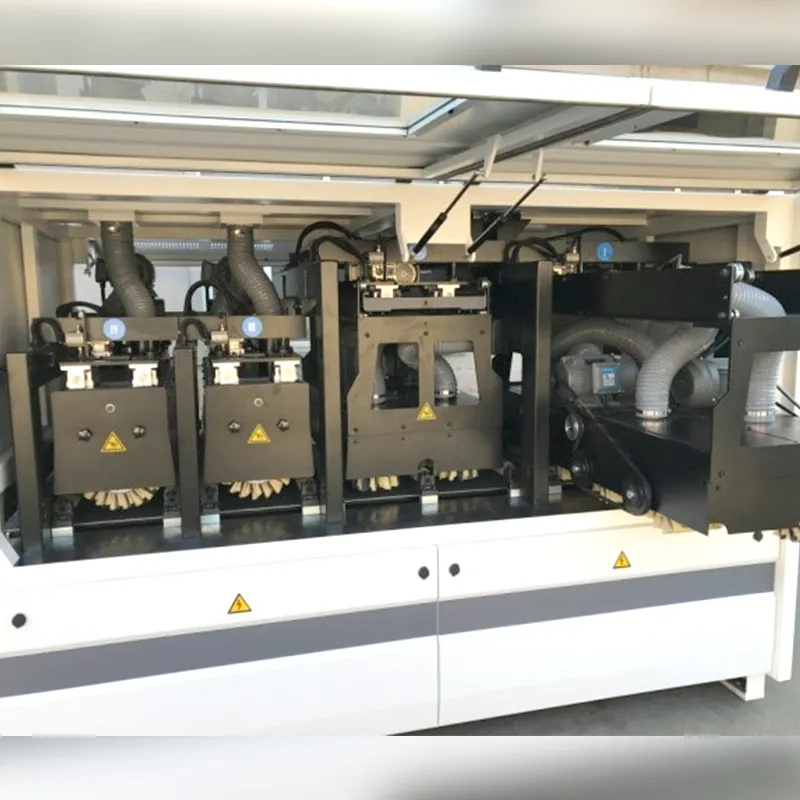

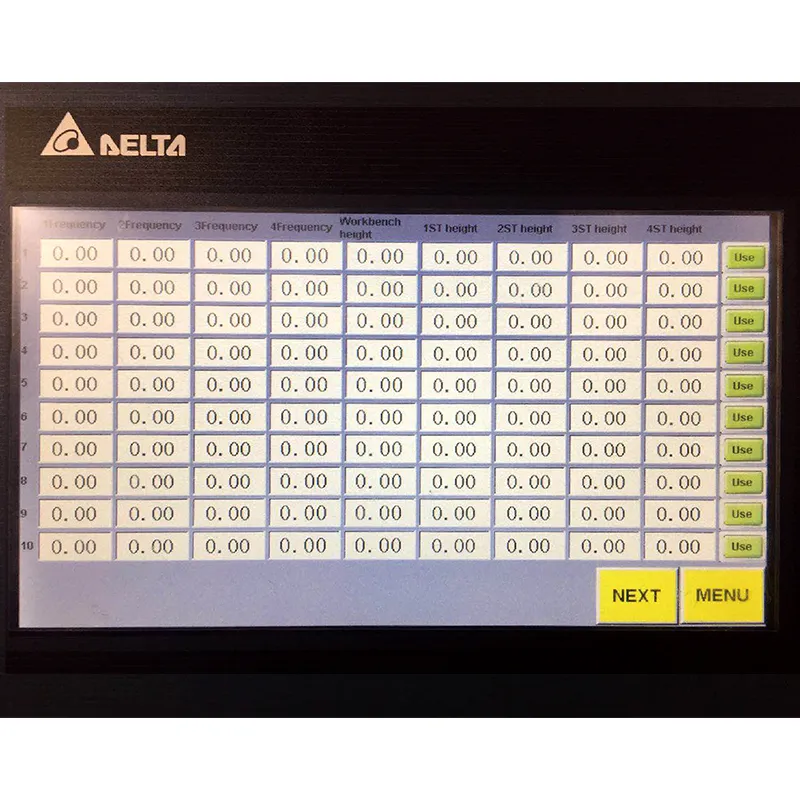

- THREE GROUPS OF SANDING UNITS CAN SAND PANELS WITH CURVED SURFACES IN DIFFERENT DIRECTIONS AND DIFFERENT HEIGHT, THAT CAN ACHIEVE THE BEST SANDING EFFECT

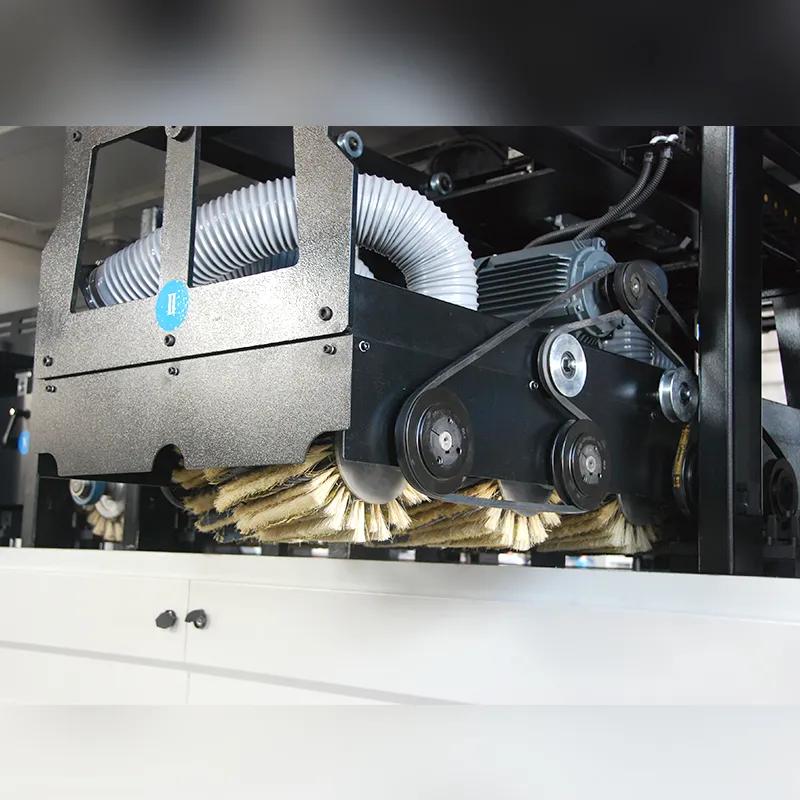

- EACH SANDING UNIT HAS 2 ROWS, WHICH CAN ROTATE IN TWO DIFFERENT DIRECTIONS

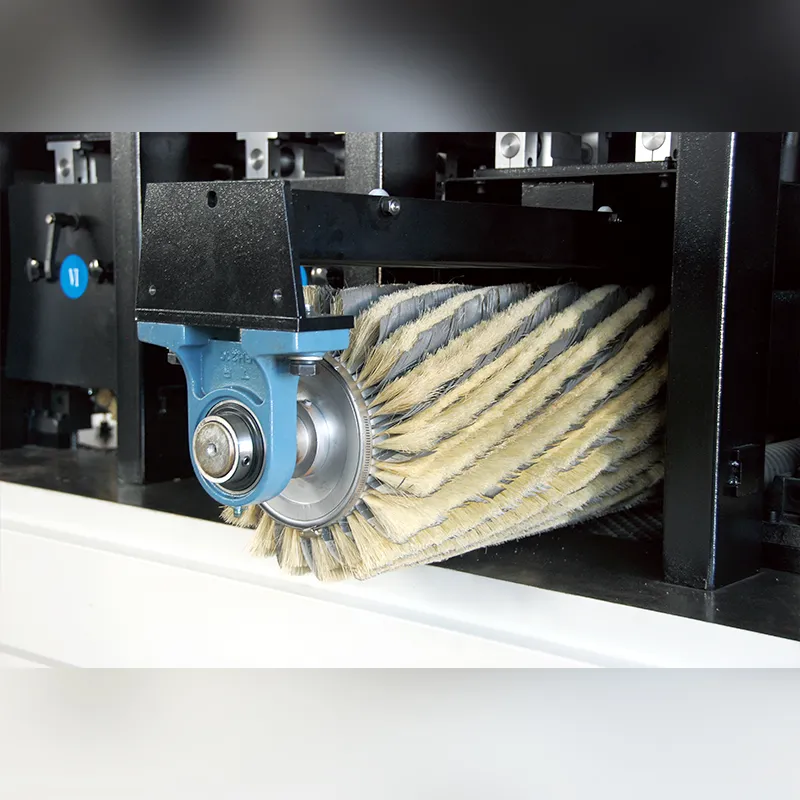

- HORIZONTAL ROLLER IS USED TO SANDING HORIZONTAL GROOVES IN PANELS, SANDING DISK IS USED TO SANDING PANELS SURFACE AND SHARP EDGES AND CORNERS

- 2 SANDING ROLLERS, USED TO SANDING PANELS SURFACE AND VERTICAL GROOVES

- EACH SANDING SHAFT CAN SWING SEPARATELY, IT IS USED TO SANDING THE SANDING MARKS CAUSED IN WORK. IT CAN MAKE PANEL SURFACE MORE SMOOTH AND CLEAN

- SANDING UNIT CAN BE PULLED OUT AS A WHOLE PART FROM 2 SIDES OF THE MACHINE, IT IS CONVENIENT TO CHANGE SANDING PAPER

| Model | HM1000R6H | HM1300R6H |

| Working width | 20-1000mm | 20-1300mm |

| Working thickness | 2-110mm | 2-110mm |

| Working length | ≥400mm | ≥400mm |

| Feed speed | 2.5-12.5m/min | 2.5-12.5m/min |

| Number of polishing roller | 8 lateral +10 disc+ 2 roller | 10 lateral +12 disc+ 2 roller |

| Total motor power | 12.85kw | 18.75kw |

| Swing scope | 50/30/15mm | 50/30/15mm |

| Speed of sucked air | ≥25m/s | ≥25m/s |

| Working air pressure | ≥0.5Mpa | ≥0.5Mpa |

| Sanding belt | 180/240/320 mesh(paper tape) for MDF, 320/400/600 mesh(cloth tape) for lacquer |

180/240/320 mesh(paper tape) for MDF, 320/400/600 mesh(cloth tape) for lacquer |

| Overall dimensions | 3600*1950*1800mm | 3600*2250*1800mm |

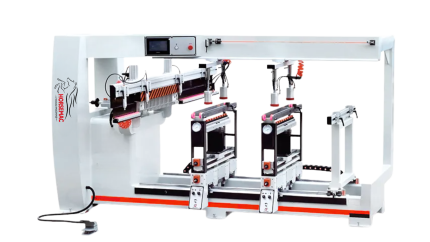

Drilling & Boring

Drilling & Boring Edge Banding

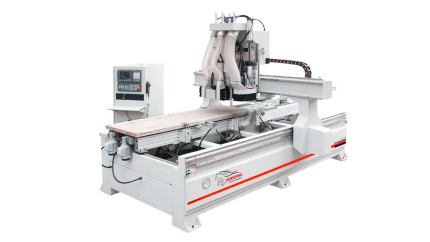

Edge Banding CNC Router

CNC Router Membrane Press Machine

Membrane Press Machine Panel Saw

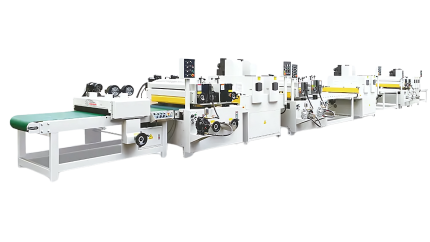

Panel Saw Sanding Machine

Sanding Machine Log Process Machine

Log Process Machine Compressors

Compressors Dust Extraction

Dust Extraction