Blog

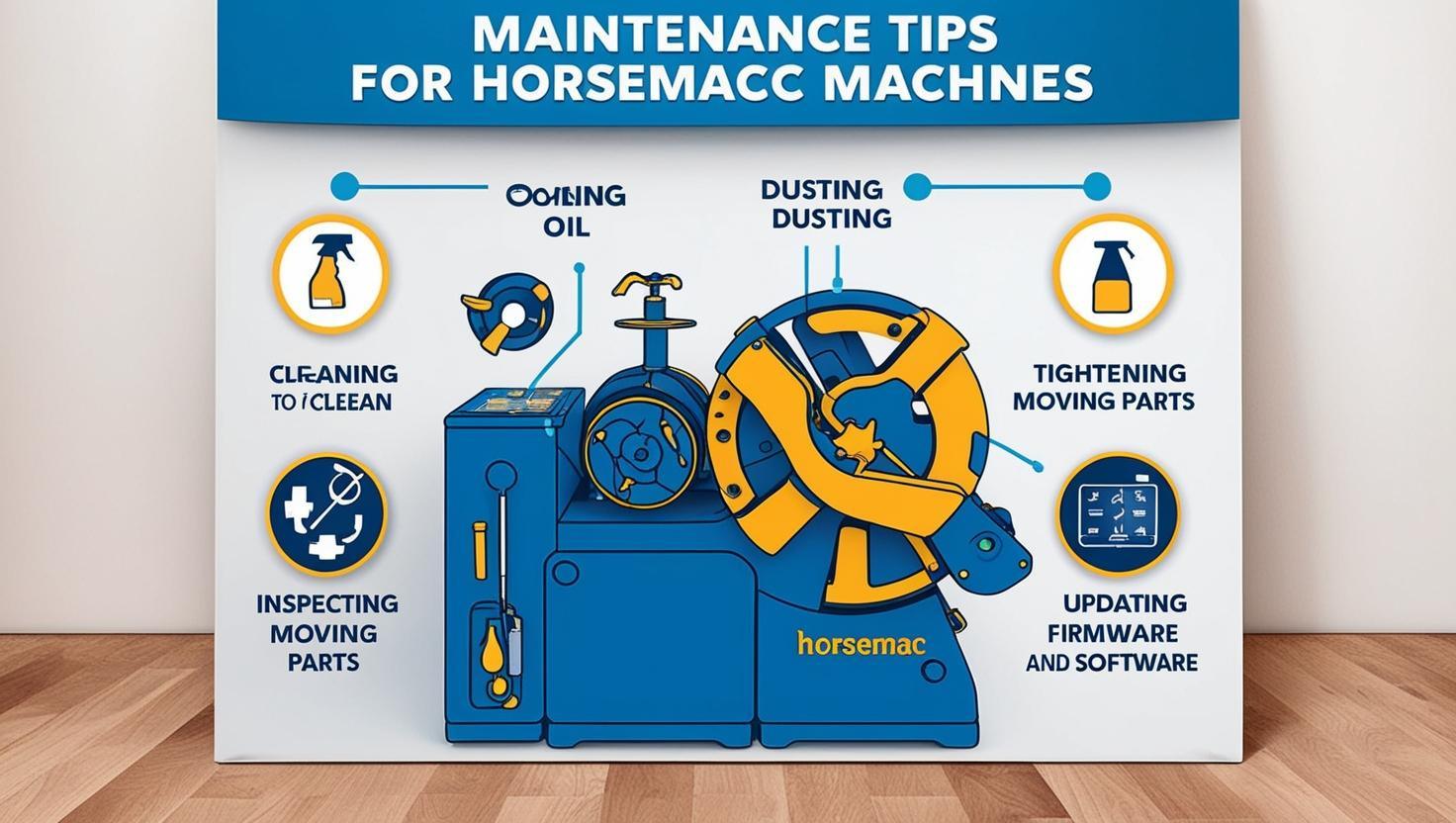

Maintenance Tips to Keep Your HORSEMAC Machines in Top Shape

Your HORSEMAC woodworking machines are built to last—but just like any powerful tool, they need regular care to perform at their best. Whether you’re a large/medium manufacturing industry, seasoned carpenter or a DIY enthusiast, following a maintenance routine can extend the life of your machines, reduce downtime, and ensure safety in your workshop.

In this post, we’ll walk you through easy and effective maintenance tips to keep your HORSEMAC machines running smoothly for years to come.

🔧 1. Clean After Every Use

Why it matters:

Dust and wood chips can clog your machines, reduce accuracy, and even damage internal parts over time.

What to do:

- Use a vacuum or air compressor to blow off dust after each use.

- Wipe down surfaces with a dry cloth.

- Clean inside dust ports and motor covers weekly.

Pro Tip:

Install a dust extraction system for cleaner operation and easier cleanup.

🛠️ 2. Check and Tighten Moving Parts

Why it matters:

Loose screws, bolts, or belts can affect performance and lead to bigger problems if left unchecked.

Checklist:

- Tighten blade nuts, motor mounts, and screws monthly.

- Check belt tension and alignment.

- Lubricate bearings and gears as per user manual.

Good to Know:

Always unplug the machine before tightening or adjusting anything.

🧽 3. Lubricate for Smooth Operation

Why it matters:

Friction can wear out parts quickly. Proper lubrication ensures smooth operation and longer lifespan.

Lubrication tips:

- Use machine oil or grease for moving parts like guide rails and lead screws.

- Avoid over-lubricating—it can attract dust.

- Schedule lubrication once every 1-2 months based on usage.

🔍 4. Inspect Blades, Bits, and Belts

Why it matters:

Sharp blades and healthy belts mean cleaner cuts and safer operation.

Maintenance routine:

- Sharpen or replace dull blades.

- Replace worn-out router bits.

- Inspect belts for cracks or slack and replace if needed.

Warning Sign:

If your machine starts making unusual sounds or burns the wood, it might be time to change the blade.

⚙️ 5. Keep Software and Firmware Updated (For CNC Machines)

Why it matters:

HORSEMAC CNC routers come with software that may receive updates to improve performance and fix bugs.

What to do:

- Check for updates from the official HORSEMAC site or your dealer.

- Backup your design files before updating.

- Recalibrate your machine after major updates.

Extra Tip:

Join HORSEMAC user forums or groups to stay updated with tips and upgrades.

🛡️ 6. Follow a Maintenance Schedule

Why it matters:

Having a fixed schedule makes it easier to stay on top of maintenance and avoid sudden breakdowns.

Simple plan:

| Task | Frequency |

|---|---|

| Surface cleaning | After each use |

| Dust port cleaning | Weekly |

| Blade check | Weekly |

| Belt & screw check | Monthly |

| Lubrication | Bi-monthly |

| Full machine inspection | Quarterly |

Print this schedule and post it in your workshop for easy reference!

📞 7. Reach Out for Professional Service When Needed

Why it matters:

Some issues need expert attention, especially with motor problems or CNC calibration.

HORSEMAC Support Offers:

- On-site servicing

- Spare parts availability

- Video call troubleshooting

- Manuals and training videos

Don’t delay service if your machine starts acting up—it could prevent bigger repairs later.

Final Thoughts

Just like a car or any high-performance tool, your woodworking machine deserves regular TLC. Following these simple maintenance tips can help you protect your investment, improve work quality, and avoid frustrating breakdowns.

Remember: A clean, well-maintained machine is a happy machine. 😊

Need help or spare parts? Contact our HORSEMAC service team for expert advice and support.

Stay tuned for our next blog post: “CNC Router Basics: Getting Started with HORSEMAC CNC Machines.”

Drilling & Boring

Drilling & Boring Edge Banding

Edge Banding CNC Router

CNC Router Membrane Press Machine

Membrane Press Machine Panel Saw

Panel Saw Sanding Machine

Sanding Machine Log Process Machine

Log Process Machine Compressors

Compressors Dust Extraction

Dust Extraction